Three stages of Annealing

Jun.05,2017

Annealing is a heat treatment designed to eliminate the effects of cold working and to restore the cold-worked metal to the original soft ductile condition. Several applications for annealing are employed. First, annealing may be used to completely eliminate the strain hardening achieved during cold working; the final part is soft and ductile but still has a good surface finish and dimensional accuracy. Second, after annealing, additional cold work could be done since the ductility is restored. By combining repeated cycles of cold working and annealing, large total deformations may be achieved. Finally, annealing at a low temperature may be used to eliminate the residual stresses produced during cold working without affecting the mechanical properties of the finished part.

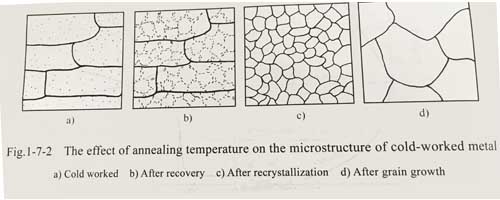

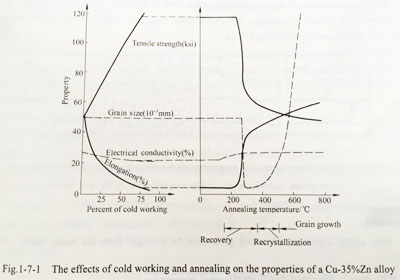

There are three stages in the annealing process. The effects of cold working and the three stages of annealing on the properties of brass are shown in Fig.1-7-1.

Recovery. Recovery, or a stress-relief anneal, is a low-temperature heat treatment designed to reduce residual stresses. The microstructure contains deformed grains which contain a very large number of dislocations in a tangled network. When we heat the metal to slightly elevated temperatures, the dislocations move and are rearranged, while the residual stresses are reduced and eventually eliminated.

However, the number of dislocations is not significantly reduced; they are instead rearranged in a polygonized structure, as shown in Fig. 1-7-2b.The polygonized structure appears to be a subgrain structure within the normal deformed grains, with dislocations forming the subgrain boundaries. Because the number of dislocations is not reduced, the mechanical properties of the metal are relatively unchanged.

Recovery restores high electrical conductivity to cold-worked copper or aluminium wire used for transmission of electrical power. The wire is strong due to the cold work and can be strung between poles placed far apart without failing, yet the wire has good electrical conductivity.

Recrystallization. Recrystallization occurs by the nucleation and growth of new grains containing few dislocations. When the metal is heated above the recrystallization temperature, approximately 0.4 times the absolute melting temperature of the metal, rapid recovery eliminates residual stresses and produces the polygonized dislocation structure. New grains then nucleate at the cell boundaries of the polygonized structure, eliminating most of the dislocations, as shown in Fig. 1-7-2c. Because the number of dislocations is greatly reduced, the recrystallized metal has a low strength but a high ductility.

Grain growth. At still higher annealing temperatures, both recovery and recrystallization rapidly occur, producing the fine recrystallized grain structure .However, the energy associated with the large amount of grain boundary area makes the fine structure unstable at high temperatures. To reduce this energy, the grains begin to grow, with favored grains consuming the smaller grains, as shown in Fig.1-7-2d.